Nothing in cart

Review of Caravans Plus Service

Delivery time is excellent.

At Caravans Plus we sell a range of 12V and 24V pumps for use in Recreational Vehicles. They range from small inline or submersible pumps, to small automatic pumps, and the extremely popular automatic pumps that can operate a shower. I will explain the differences and make suggestions.

Most of our pumps are 12 volts with just a couple that operate on 24 volts for use in buses or trucks. This is always detailed in the specification. It is recommended to have a fuse in the wiring before any electrical device. The current draw on these pumps is usually quite low and 2.5mm to 4mm wire is in most cases very adequate. We do recommend running twin wire all the way to the pump rather than using an earth to the chassis, as using the chassis often causes problems.

A pump has an ability to achieve a certain flow-rate. This is expressed as litres/minute or gallons/minute. 10 litres per min will fill a 10 litre bucket in one minute. Simple right?

A flow rate of 4 litres per minute will be OK for a shower. It is rare to use 10 litres per minute when using water from your tank in your RV so a pump that can achieve 10 litres per minute will suit all standard RVs. They will allow your sink to fill while someone is in the shower.

More is not always better, read on...

Some basic pumps just pump, and must be switched off and on by a separate switch. The Whale inline and submersible pumps fit into this category. These go direct to a straight through spout or shower rose without a tap. They are stopped by switching the pump off with a switch.

The majority of the pumps we sell are automatic and start pumping as soon as a tap is turned on. They have a pressure sensor built in and will start to pump when the pressure inside the outlet pipes is less than the cut-off pressure. This will be expressed as PSI or bar.

We try to include both metric(bar) and imperial(PSI) versions. If we omit it, 14.5psi = 1 bar. When the pressure reaches the cut-off pressure they will stop pumping. This prevents excess pressure on all plumbing components and appliances within the plumbing system. Mains pressure in Australia should be around 5 bar but can get as high as 8 bar.

Some RV appliances simply cannot withstand this pressure and a pressure limiting device is recommended where a hot water system is installed. At the current time the TRUMA HWS requires a pressure limiting device.

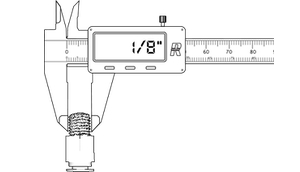

Other common HWS that do not require one are the SUBURBAN and ATWOOD HWS. Flow-rate and Pressure can be affected by the diameter and lengths of the pipes used. For most RVs we recommend 12mm or 1/2 inch hose as suitable.

Cycling of the pump occurs when the pump switches off and on many times when you are having a shower. This can happen when the flow rate for the pump exceeds the rate you are using the water. If the pump is rated at 10 litres per minute and you have the tap only half on using say 5 litres per minute this will cause cycling.

The pump must stop until the pressure in the pipe reduces. As soon as it drops below a preset value the pump starts again. This causes the pump to switch on and off, sometimes quite quickly. There are a number of ways to reduce or eliminate this problem.

1) Placing an accumulator between pump and outlet

2) Getting a variable speed pump

3) Having a pump with built-in bypass

An accumulator can be thought of as a balloon.

Any excess flow produced by the pump that is not allowed to exit the tap, can go into the balloon. When the balloon is full, the pump will stop and the water will still flow from the tap until the balloon is empty. Then the pump starts again and repeats the sequence.

Depending on the size of the accumulator this can dramatically reduce the number of times the pump must stop and start, therefore the cycling will be reduced.

Variable speed pumps are more expensive and speed-up and slow-down to give the same pressure at the flow rate you require. While these are well establishing for the residential and industrial market, the small size pumps used in RVs tend to be less than reliable, considering the purchase price.

By-pass pumps. The latest generation of quality RV pumps have a bypass built into the pump. This means that when the pressure increases, some of the water that gets pumped actually goes back to the inlet side to be pumped again. So the pump keeps pumping. There is a limit to the amount that can go through the bypass or else the pump would never stop. It reduces the cycling without the need for any accumulators or electronic variable speed pumps.

They can still cycle at very slow flow rates, but these are the pumps Caravans Plus recommends in new RV installations and when replacing existing pumps. The most popular pump we sell has this and is shown below, it replaces the Shurflo 2088 pump that did not have the bypass feature.

Filters are recommended to prevent dirt and other debris entering your pump and causing damage to the diaphragm. Damage caused to a pump from dirt will not be covered by warranty. These should be placed on the inlet side of the pump and placed where they are readily accessible for cleaning.

The use of non-return valves (also known as check valves) ensure that water is only able to flow one way, eliminating the chance of flow black. They are particularly useful when keeping a water line constantly primed, or water to the pump.

Most pumps will suck up water from the tank to the height of the pump. This will be detailed in the specifications as Dry Prime height.

A small number of inexpensive pumps need to be at or below the water level as they cannot pump air to get the water flowing. As a pump wears it may not hold water in the inlet pipe when the pump stops. This makes it necessary to pump air each time until the pump is primed. You could place a non-return valve in the pipe, but that will also restrict flow. For a permanent solution you should renew the diaphragm or replace the pump.

While not really a feature of any particular pump, it is important to mount the pump correctly to prevent fatigue of fittings and annoying vibrations. The mounting points should be at a solid location, not on a sheet of ply without any bracing. This is not for strength, but to prevent the mounting surface acting like the skin of a drum, vibrating in time with the pump.

The Shurflo range of pumps will operate in any position, however if space permits you should consider placing it horizontal to reduce pressure on the mounting points.

It is good practice to install the pump somewhere accessible for servicing as most pumps have a built in thermal protection cut out. This area should be a well vented space to avoid accidental cut out due to premature overheating.

Another very important item is the connecting pipe work. This must be flexible so the vibration of the pump is not transferred through the pipe to another location that can make a noise. One common approach is to use about 300mm of flexible hose with a bend before fitting it to any straight or rigid pipework. The vibration will then get lost in the curved section if it has room to move freely.

Some pumps can run dry without damage, and this is a feature to look for in the specifications. Any pump that does not have this feature can be quickly ruined if it runs without any water to keep it cool.

Each pump will show what water connections are on the body of the pump and if any additional adapters are included.

Our website has a unique feature that shows all the other fittings we sell that will connect to the pump inlet and outlet. These are listed as CONNECTIONS shown below the pump description. Try this feature as it ensures the parts will connect together, we guarantee it!

So to conclude, when deciding which pump is best for your application remember to consider:

And as a last comment, noisy pumps are generally due to vibration transferring from the mounting surface or from rigid pipework transferring the vibration.

Delivery time is excellent.

Great service. Can highly recommend.

Super fast service.

17 Comments

Dan

location of pump eg caravan water suply is at the very low side of the van. should the pump be down close to the source or higher up, say, under the kitchen sink?

Steve - CaravansPlus

Pumps should be closer to the source (tank) not the outlet. Pumps are much better at pushing water than pulling it. For most pumps, pulling heights of 1m or so is fine as long as you use a rigid pipe such as John Guest.

Malcolm

What difference does the PSI make. If the flow rate is for example 10lpm and the pump is 40 PSI or 20PSI what happens

Londa

Why would our 12volt shurflow pump just suddenly stop it is only 1 month old ?

Desmond

Our pump 6 years old is very noisy and with a tap on will come on and off without a tap being turned on

Syd Sunter-Smith

Please advise me what pump I need to replace the Flow King 1 ...Model no 2095...10.6 L/min in my 2004 Jayco Heritage. Cheers Syd SS

Brian

Thanks for this info good advice

Tasmsn

Hi Mike, my Shutflo Accumulator seems defunct, not holding any pressure at the valve. It's coupled to a Shurflo pump (24v) of the previous generation . Manual says throw the accumulator away , get a newy , but was considering going to the new gen 4009 Shurflo but I've read conflicting articles about this version's need for an accumulator ?...do you reckon a new pump without the buffer is ok?...the current one has been full time operational for nearly three years .

Mike - CaravansPlus

The Shurflo 4009 is advertised by the manufacturer as not requiring an accumulator as it is a bypass pump. This is not to say it is completely immune to cycling in some certain installs. We have had some customer feedback which indicates it is advantageous to include an accumulator in your plumbing system where an instantaneous hot water unit is being used. Off course this is is also highly dependent on the hot water system being used. Some are a little more restrictive than others. If you are experiencing cycling with a 4009 of which is feeding a instantaneous hot water system, then by all means add an accumulator to the outlet port. I hope this helps.

Terry

What pressure should an accumulator be set at if the pump is a 40 Psi pump

Paul

Hi is this pump suitable for farm spraying of chemicals? Thanks

Geoff

I installed a Shurflo 4009 pump to replace a noisy chinese pump in my caravan. The trouble is it pumps in the opposite direction. I swapped polarites but it is still in the wrong direction. Is there an easy fix or do I have to swap my plumbing around?

David

Hi, installed today my 4009-101-A87 (to replace the 2088-403-144 pump initially installed from new in van -2012) ...and pumps well. Only problem is when I turn the tap off, it takes 3 secs to stop the pump action (thats okay) but the worrying part is a further 10-14 secs I hear a clicking from the motor like its "trying" to turn off but just cant. Also in this 10-14 sec period the bathroom light flickers. No other light flickers. I have repeated the above 3 times with same results. Had a look at manual but buggered if I can see how.... or IF.... I need to adjust flow rate. Any assistance appreciated. Many thanks. Dave, PERTH

David C

Had the exact same problem with my 4009 pump. Think the clicking noise was coming from the bypass valve (it may have been sticking). This is what I did, it took a bit of adjustment but it appears to be working fine now. I adjusted mine with the pump running . First adjust the pressure switch, this adjustment screw will actually turn the pump on and off. Next turn the shower on to normal operating pressure and adjust the bypass screw until the pump stops cycling and you can hear the water bypassing in the pump. Hope this helps.

Gye

How does pumping from a flexible bladder affect the need for breathers? Also, is there likely to be pockets of water created as the bladder collapses / empties?

Trevor

Have a Dec 2020 Built Caravan with a Surflow 4009 water pump. The van has travelled 12,000 - 15,000 ks and the pump started leaking on our last trip (water dripping from under the die cast casing). About two - three weeks after returning from our last trip I opened up the van to check the water pump, turned on the 12volt pump switch and tried to use the water taps, nothing happened. The fuse had blown. On checking the system the water pump had seized up due to water flow into the bearings through the leaking diaphragm in the pump. The Surflow 4009 Water pump has been rarely used as we have only spent a few nights without water connected to the van. Very poor performance from this pump. All four diaphragms had split causing the leak into the bearings and freezing the motor with rusted bearings. Not impressed with the Surflow 4009 water pump. I will fit a new one and see how that goes but that's were it ends with Surflow pumps if there is a repeat of this poor performance.

John

Trevor, I,ve installed 3 of those Shurflo 4009 pumps. One came with the van, others from caravan dealers. Everyone died like yours, from internal leaks and corrosion. All lasted slightly more than 12 months. I’ve always liked Shurflo but consider this model a complete piece of crap. Will definitely never use another one, and would have reservations about using any of the Shurflo pumps produced for the caravan industry.